Editor’s note: Guest author Dr. Ammie Chittim is a geoarchaeologist who earned the Ph.D. degree in anthropology at the University at Buffalo, Masters degrees at the University at Buffalo and the University of Toronto, and a Bachelor of Science degree at Bridgewater State University, with studies in both archaeology and geology. Her website is nepsarchaeology.org. The petrographic research reported here has been supported by the Robert E. Funk Memorial Archaeology Foundation, Inc., the Mark Diamond Award (University at Buffalo), the New York Archaeological Council Student Paper Prize, Mr. John McKendry, the Elfrieda Frank Foundation, and the Archaeological Conservancy. Dr. Chittim thanks Dr. John Hart and the staff of the New York State Museum, the SUNY Geneseo Anthropology Department, the Marian White Museum (University at Buffalo), and the Seneca Iroquois National Museum for access to their archaeological collections for this analysis.

What is Petrography?

Petrography is an analytic method borrowed from the fields of Paleontology, Geology and Mineralogy. The petrographic method can provide basic structural information on an object through the systematic estimation of its micro components, such as the minerals within rocks, presence of organic material, and empty spaces. Petrography is a starting point for analysis; the basic technological information it provides is designed to be built upon by later analyses. Almost any object can undergo petrographic analysis, although it is most commonly used on rocks, fossils, soils, wood, bones, teeth, and pottery.

The Utility of Ceramic Petrography in Archaeology

Petrographic analysis is a routine aspect of post-excavation analysis in most parts of the United States and Internationally. There are many advantages to ceramic petrography, including the ability to obtain information regarding the vessel’s manufacturing processes, from raw materials to final firing conditions. Petrography allows for a more scientific way for the technical aspects of artifacts to be compared within and between sites. Ceramic petrographers are trained to calculate the relative percentages of temper, plastic inclusions, and voids (empty spaces) within the object’s matrix through a process known as point counting. These relative percentages can be later statistically compared. This creates a more accurate, more objective, and reliably reproducible data that can be more easily discussed by colleagues. Better communication leads to better classification. The process of thin sectioning an artifact also produces a permanent record that can be reused by any future student of petrography. Archaeologists can use the data obtained from the petrographic method to establish relative chronologies, establish the origin of the ceramic and lithic materials, indicate exchange mechanisms, and compare the technical aspects of ceramic materials within and between cultural regions. Petrographic data provide a descriptive account of how a particular object was constructed; therefore, it can be combined with any theoretical paradigm to provide an explanation for why variation and change occurs in human technology.

What Resources are Needed?

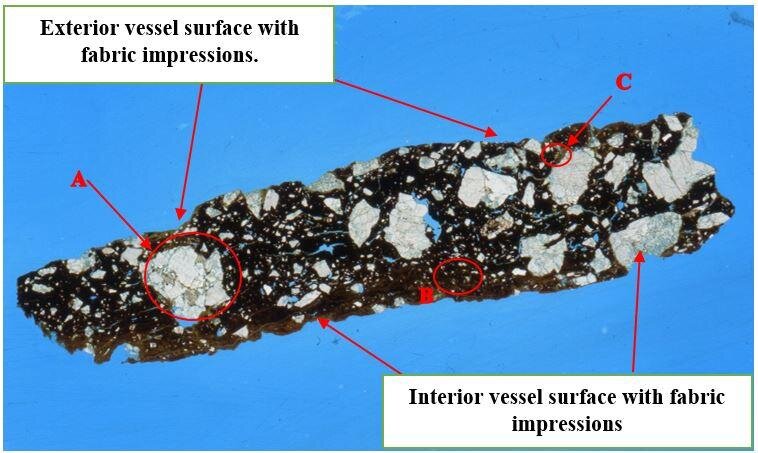

Petrography is relatively low-tech; thin sections of an artifact are the only equipment that must be purchased for every study. A petrographic microscope and a trained analyst are required for the analysis. Non-required but useful additional items include reference material for making comparisons (Barraclough 1992; Freestone 1995; Matthew et. Al 1991; Orton and Hughes 2013, Powers 1953, Quinn 2013), a high-resolution scanner (Figure 1), a camera, and a live feed video that feeds to a monitor or television screen. The high-resolution scanner can be used to take high-quality scans of individual slides prior to analysis. A camera that attaches to the petrographic microscope or a handheld microscope are useful for taking photomicrographs (Photo 1) and pictures of the ceramic fabric (Photo 2). And a live-feed video that transmits to a screen eases the eye strain associated with staring into a microscope for hours each day.

Figure 1. A high-resolution scan of MacCauley Complex 5 V1B1 showing the orientation of the slide cut perpendicular to the rim and the different types of aplastic inclusions. The blue background is the remaining oil that the sherd was cut in. The black arrows point to different surface treatments visible on the slide. Letter A is encircling a large, angular grit fragment. Letter B indicates an area of small, angular and rounded glacial flour. And Letter C is pointing out a fragment of grog. Image courtesy of the New York State Museum (after Mitchell 2017:Figure 5.2).

Photo 1. Image of a poorly sorted fabric containing angular coarse-crystalline crushed rock from Nine Mile Road, V1B2. Image taken at 10x in plain polarized light.

Photo 2. Image of a thick section taken of Sinking Ponds V2B1. Note the two different types of temper present, isolated quartz and crushed rock fragments. Thick sections are produced during the thin sectioning process and are useful for making general observations about each sample. Image taken with a handheld DinoLite microscope, at 10x.

What is the Relative Cost of Petrographic Analysis?

The cost of thin sections varies between companies and is dependent upon how porous and therefore fragile a sample is. More porous objects, such as earthenware pottery, must be impregnated with epoxy prior to cutting or else the sample will disintegrate. Generally, individual petrographic samples can be produced for $18-30/sample. The cost of sample analysis varies greatly between companies, starting from about $200.

Case Study: Challenging the Foundation of Ritchie’s Vinette Type Series

The adoption of the petrographic method has lagged in areas still heavily dependent upon cultural types. In the Northeast, Dr. William A. Ritchie is a key figure in the construction of culture types. Ritchie describes the basic types for early pottery, including the Vinette Series in his 1949 publication. The Vinette pottery types are part of the Point Peninsula Series: Vinette 1, Vinette Dentate, and Vinette Complex Dentate. These pottery types roughly correspond to the Early and early Middle Woodland periods, 3000-2100 BP (1000-100 BC) in New York State and are believed to be the earliest known pottery in the Northeastern Woodlands. The authors believed the Vinette type pottery developed from the earlier, steatite stone bowl technology (Boyd 1962; Ritchie 1965; Ritchie and Funk 1973; Truncer 2004; Witthoft 1953) and was predecessor to later, better developed Owasco ceramic types. Their divisions between the Point Peninsula and Owasco ceramic traditions were based on following attributes: decorative design, construction technique, and temper.

Reexamining Ritchie’s Vinette Series Using Petrography

In order to challenge the Vinette pottery type series (Ritchie and MacNeish 1949), the author focused on the technological traits recognized as key identifiers: specifically, the amount and size of temper, and forming and firing techniques in relation to surface treatments and design techniques. This study included 30 undecorated Vinette 1 vessels, three decorated Vinette 1 vessels, eight undecorated Vinette Dentate vessels, nine decorated Vinette Dentate vessels, two Vinette Complex Dentate vessels, one Vinette Variant vessel (see Figure 2). A total of 120 petrographic slides were analyzed (Mitchell 2017).

Figure 2. Location of sites examined: 1. McKendry, 2. Zoar Valley, 3. Sinking Ponds Wildlife Sanctuary/the Sinking Ponds site, 4. Hunter’s Creek County Park, 5. Como Lake County Park, 6. Chestnut Ridge County Park, 7. Vinette, 8. Wickham, 9. Vine Valley, 10. Scaccia, 11. Gardepel, 12. Ferguson, 13. Cottage, 14. Felix, 15. Riverhaven No. 2, 16. Broken Clock, 17. Macauley Complex, 18. Ninemile Road, 19. Saint Bonaventure, 20. Portage, 21. Renaissance House, 22. Mouth of Cattaraugus Creek, and 23. Simmons.

Petrographic Results

The results of this study show each of Ritchie’s assumptions regarding the differences that delineate the Vinette types are false (Mitchell 2017). Table 1 summaries the traits by type as defined by Ritchie and MacNeish, alongside the results of this study. The results show that there is more variation present in early ceramic technology than is accounted for in Ritchie and MacNeish’s types. Significant variation exists in the clay sources selected, the type of rock (quartz, feldspar or mafic-rich varieties), the amount of crushed rock added to the matrix, the ways in which vessels were formed (coiled or coiled with secondary smoothing treatments), and firing atmosphere and temperature conditions. In addition, the descriptive method used by the authors is subjective and difficult to accurately reproduce.

Table 1. Summary of Traits Used by Ritchie and MacNeish (1949) to Divide Types Within the Vinette Series and Petrographic Results (from Mitchell 2017 Table 7.17)

Significance

Early vessels in New York State are tempered with coarse-crystalline metamorphic and igneous crushed rock temper obtained from glacially derived features (Mitchell 2017:130-133). The intentional selection of these rocks is the key to understanding early ceramic technology in New York State. Based on the presence and treatment of the rock used as a tempering agent, the author believes that early ceramic technology in New York State arose from the older practice of earth oven cooking (Mitchell 2017:207-226) and not steatite stone bowl technology (Manson 1948; Mason 1981:209; Ritchie 1965:151; Ritchie and Funk 1973:96-98; Truncer 2004, 2005). Additionally, the production of ceramic technology in the Northeast is neither haphazard nor opportunistic (Ritchie and Funk 1973: 71-73; Truncer 2004). The repeated pattern of crushed coarse-crystalline metamorphic and igneous rock as temper in early ceramic vessels is evidence of structured agency and practice in motion (Dobres and Hoffman 1994; Giddens 1979, 1984; Gosselain 1992, 200; Hegmon 2003; Joyce and Lopiparo 2005; Lemonnier 1983; Leroi-Gourhan 1964; Pauketat and Emerson 1991). For the purposes of this study, agency involves the choices of raw material and the method of production for each individual vessel examined. What choices are perceived of as available are socially generated; this is the structure behind the technology. The practice identified by this project is the selection of non-sedimentary coarse-crystalline rock as temper. The repeated selection of this rock over any other material across all of New York suggests continuity in knowledge between potters within the chaîne opératoire production.

Concluding Remarks

Petrographic analysis is required to identify temper and technological features of artifacts. Ideally in every archaeological project a budget should be set aside for petrographic testing, just as funds are set aside for AMS 14C dating. Types of technological information that can be obtained from the petrographic method includes mineral identification, grain-size distribution, ceramic matrix heterogeneity, manufacturing technique through the alignment of inclusions, firing atmosphere and maximum temperature, and estimates of the relative percentage of temper and isolated mineral present in the matrix. The current lack of a dataset of petrographic fabrics makes conversation about why and when specific tempering materials may have been selected for or avoided through time remains unclear. Future petrographic thin section analysis on ceramic material across the Northeast needs to be conducted. When this analysis is coupled with radiocarbon assay on pot residue, it may establish a more reliable chronology and a better understanding of ceramic technology and human behavior through time. The creation of a new ceramic database, which contains information regarding the type, amount, and appearance of temper, natural inclusions, and voids, forming techniques, and firing atmospheres, can be combined with morphological and surface treatment data, and give archaeologists the freedom to move past the restrictive type system and its associated complications.

References Cited

Barraclough, A.

1992 Quaternary Sediment Analysis: A Deductive Approach at A-Level. Teaching Geography 17:15-18.

Benco, Nancy L. The Early Medieval Pottery Industry at al-Basra, Morocco. BAR International Series 341. British Archaeological Reports, Oxford.

Bishop, Ronald L. and Frederick W. Lange (editors)

1991 The Ceramic Legacy of Anna O. Shepard. University Press of Colorado, Niwot.

Boyd, Glenda F.

1962 The Transitional Phase on Long Island American Antiquity 27(4):473-478.

Dobres, Mareia-Anne, and C.R. Hoffman

1994 Social Agency and the Dynamics of Prehistoric Technology. Journal of Archaeological Method and Theory 1(3):21 1-58.

Freestone, Ian C.

1995 Ceramic Petrography. Science in Archaeology: A Review 99(1):111-115.

Giddens, Anthony

1979 Central Problems in Social Theory: Action, Structure, and Contradiction in Social Analysis. University of California Press, Berkeley.

1984 The Constitution of Society: Outline of the Theory of Structuration. University of California Press, Berkeley.

Gosselain, Oliver P.

1992 Technology and Style: Potters and Pottery Among Bafia of Cameroon. Man, New Series, 27(3):559-586.

2000 Materializing Identities: An African Perspective. Journal of Archaeological Method and Theory, 7(3):187-217.

Hegmon, Michelle

2003 Setting Theoretical Egos Aside: Issues and Theory in North American Archaeology. American Antiquity 68(2):213-243.

Joyce, Rosemary and Jeanne Lopiparo

2005 Post Script: Doing Agency in Archaeology. Journal of Archaeological Method and Theory. Vol. 12(4):365-374.

Lechtman, Heather, and Arthur Steinberg

1979 The History of Technology. In The History and Philosophy of Technology, edited by G. Bugliarello and D. B. Doner, pp. 135-160. University of Illinois Press, Chicago.

Lemonnier, Pierre

1986 The Study of Material Culture Today: Toward an Anthropology of Technical Systems. Journal of Anthropological Archaeology 5:147-186.

Leroi-Gourhan, André

1945 Evolution et techniques. Milieu et techniques. Albin Michel, Paris.

Manson, Carl

1948 Marcey Creek Site: An Early Manifestation in the Potomac Valley. American Antiquity 13(3):223-227.

Mason, Ronald J.

1981 Great Lakes Archaeology. Academic Press, New York.

Matthew, A.J., A.J. Woods, and C. Oliver

1991 Spots Before the Eyes: New Comparison Charts for Visual Percentage Estimation in Archaeological Material. In Recent Developments in Ceramic Petrology. Edited by Andren Middleton and Ian Freestone, 81:211-263, British Museum Occasional Papers.

Mitchell, Ammie M.

2017 The Symbolism of Coarse Crystalline Temper: A Fabric Analysis of Early Pottery in New York State. Ph.D. Dissertation. SUNY at Buffalo, Buffalo, New York.

Orton, Clive and Michael Hughes

2013 Pottery in Archaeology. Cambridge: Cambridge Press.

Pauketat and Emerson

1991 The Ideology of Authority and the Power of the Pot. American Anthropologist, New Series 93(4):919-941.

Powers, M.C.

1953 A New Roundness Scale for Sedimentary Particles. Journal of Sedimentary Petroleum, 23:117-119.

Quinn, Patrick Sean

2013 Ceramic Petrography the Interpretation of Archaeological Pottery & Related Artefacts in Thin Section. Archaeopress, Oxford.

Ritchie, William A.

1980 [1965] The Archaeology of New York State. Bantam Doubleday Dell Publishing Group, New York.

Ritchie, William A. and Robert E. Funk

1973 Aboriginal Settlement Patterns in the Northeast. The University of the State of New York, Albany.

Ritchie, William A. and Richard S. MacNeish

1949 The Pre-Iroquoian Pottery of New York State. American Antiquity 15(2):97-124.

Sassaman, Kenneth E.

1993 Early Pottery in the Southeast: Tradition and Innovation in Cooking Technology. The University of Tennessee Press, Knoxville.

Sheppard, Anna O.

1965 Ceramics for the Archaeologist. Publication 609. Carnegie Institution of Washington, Washington, D.C.

Stoltman, James B.

1989 A Quantitative Approach to the Petrographic Analysis of Ceramic Thin Sections. American Antiquity 54 (1):147-160.

Truncer, James

2004 Steatite Vessel Age and Occurrence in Temperate Eastern North America. American Antiquity 69(3):487-513.

2006 Taking Variation Seriously: The Case of Steatite Vessel Manufacture American Antiquity 71(1):157-163.

Williams, D.

1983 Petrology of Ceramics. In Petrology of Archaeological Artifacts, edited by D. Kemp and A. Harvey, pp. 301–329. Clarendon Press, Oxford.

Witthoft, John

1953 Broad Spearpoints and the Transitional Period Cultures. Pennsylvania Archaeologist 23(1):4-31.